Production Order Processing (POP)

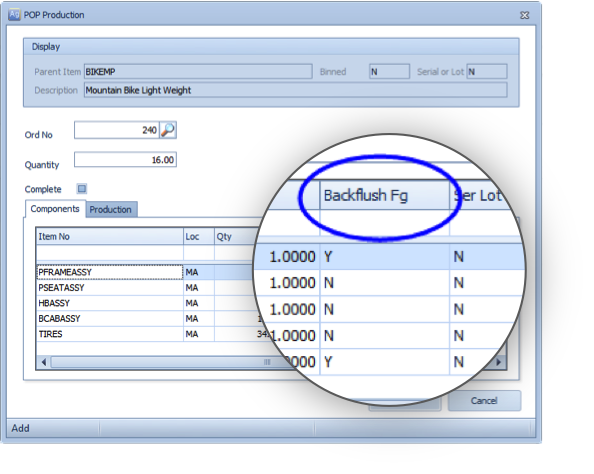

The Production Order Processing (POP) module from Macola provides users with a simple and powerful lean process designed to backflush Bill of Material Components and record finished good inventory. WiSys POP takes these very same Macola POP backflush processes to the production floor and allows the users to transact in real-time. Users transfer inventory to staging bins in the production area and then report production as it occurs either from a handheld device or a desktop. The material in the staging bin is then back flushed just as it is in Macola.